BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

URL: http://journal.iehfs.ir/article-1-530-en.html

2- Department of Occupational Health, School of Public Health, Hamadan University of Medical Sciences, Hamadan, Iran

3- Department of Occupational Health Engineering, Environmental Health Research Center, Research Institute for Health Development, Kurdistan University of Medical Sciences, Sanandaj, Iran ,

According to national and international law, staff exposure to ergonomic risk factors and musculoskeletal disorders must be managed (1,2). Many work schedules include manual tasks that often put the individual at risk for ergonomic factors. In ergonomics, any occupational task that one has to use the body to carry, lift, lower, push, pull, hold objects, people and animals is manual tasks. Manual tasks cover a wide range of activities, from arranging items on shelves, working on conveyor lines or entering data into computers to transporting patients and working with vibration tools. There are countless international statistics showing that staff involved in handicrafts experience many musculoskeletal disorders (3-5).

One of the most important and effective approaches that can reduce the burden of musculoskeletal disorders in the workplace is Participatory Ergonomics: PE. A common element in all participatory ergonomics programs is the promotion of knowledge and skills of employees in the field of ergonomics and their participation in the design and implementation of ergonomic interventions.

Manual tasks are the Participatory Ergonomics for Manual tasks: PErforM. This method (PErforM) has been applied in many industries including electronics and metal industries (6), automotive manufacturing (7), manufacturing (8), construction (9), health care systems (10,11) and underground coal mines (12).

The present study describes the step-by-step implementation of a performance plan in a manufacturing company over the years 2016 to 2017 and presents some simple, low-cost, and early benefit interventions reminding the positive outcomes of managing ergonomic risk factors of manual tasks. The main purpose of this program was to reduce the risk of injuries related to the manual duties of the production company employees.

The organization involved in this study is a resin manufacturing company with about 100 staff members classified in the vertical chemical industry group. The purpose of this program was to explain and develop the risk management system and stimulate the creativity and imagination of employees through participatory ergonomic processes. Therefore, a part of a performance program implemented in one of its lines with 20 workers (who participated consciously in the program) was included in this study.

Using the performance program, team members identified the ergonomic risks involved, assisted the risk management structure through the risk assessment process that requires control suggestions, proposing and planning how to implement improvement controls; ultimately they determined how the proposed controls are to be evaluated. Finally, in cases where complex problems are difficult to solve, the commitment of management and assistance from an ergonomics specialist outside the organization will be helpful. The steps for implementing a performance plan in this study include:

Step One: Forming a Performance Ring, Choosing a Performance Champion, and Training the Performance Structure

Step Two: Screening for Lines / Jobs at High Risk for Musculoskeletal Disorders

Step Three: Providing on-the-job training to employees with hazardous manual jobs

Step 4: Identifying and Evaluating Ergonomic Risk Factors for Handicrafts

Step Five: Identifying the Affected Physical Areas and the Intensity of Each Ergonomic Risk Factor

Step Six: Teaching Improvement Interventions to Working Teams and Collecting Suggested Interventions using the Dotmocracy Method (Figure 1)

Step 7: Determining the best intervention and implement it

Step Eight: Continuous monitoring

Figure 1: Overview of the Dotmocracy method to achieve the best recovery controls in the performance program

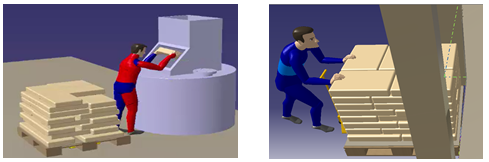

At the end of the first run of the performance program, the two tasks of (a) pushing the pallets containing the bag, 800 kg (twice per 8-hour shift), and b) charging the machines with the 25 kg bags. Pallets (twice per shift and at least 60 minutes each time) were identified as the most risky manual tasks in this part of the company. Also, the hands, shoulders and lower back were most affected by these risky manual tasks. In Figure 2 you can see an example of these two risky manual tasks.

Figure 2: An example of high-risk manual tasks identified by work teams

The ergonomics consultant also used simulations of tShese high-risk tasks for biomechanical and ergonomic analysis (Figure 3).

Figure 3: Simulation of two hazardous manual tasks in the Katya environment

Suggestions collected by the dotmocracy method, which, while cost-effective, gained the most general agreement to improve the two hazardous manual tasks identified included items below (Figure 4):

1. Charging machines with 25kg bags on pallets in group

2. Push and pull (load shift) 800 kg pallets in batch

Figure 4: Real-time simulation of two proposed interventions for two high-risk manual tasks

Performing the task of charging the machines with 25 kg bags reduced repetitive movements in the hand, waist and shoulder. Also, the task of pushing and pulling (shifting) pallets of 800 kg also reduced the amount of force applied on lumbar, shoulder and arm exercise.

In this study, a performance program which is a participatory-based program, was introduced to Iranians to manage the risk factors of ergonomic manual jobs. The main purpose of the program was to enhance the ergonomic knowledge of employees, to engage them in identifying, evaluating and providing ergonomic improvement strategies.

As in the present study, many researchers, including Strucker et al., used the "performance program" in different work environments with high-risk manual tasks (12,13) and studied the effectiveness of the performance program to reduce the risk of associated ergonomic injuries (13). The results of this study suggested that staff recovery interventions and the usefulness of participatory ergonomics are consistent with previous studies (19-14). The effectiveness of participatory ergonomics programs in enhancing job satisfaction (20), improving cargo handling conditions (21,15), designing work environment equipment (15,14), physical work environment and work management planning (14) has also been confirmed. But Rovilis et al. believe that the impact of participatory ergonomic interventions on employee health is not certain (17).

Given the manual tasks of the staff in this manufacturing unit, it seems reasonable to adjust the risk factors of two manual occupational tasks as part of the PErforM collaborative ergonomics program implemented in a limited part of a manufacturing company. In future studies, it is suggested that in addition to the management commitment and involvement of more staff, the time to adapt to longer interventions should be considered.

The authors thank all those who helped them writing this article.

The authors declared that there are no conflicts of interest.

Received: 2018/07/25 | Accepted: 2019/07/8 | ePublished: 2019/11/11

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |